MUSAICS REPAIRS SERVICE

Musacis is located in Tecoma, outer east of Melbourne.

I offer repairs to classroom and concert tuned and non tuned percussion.

This includes re tuning, replacing rubber components, adjustments etc. to xylophones, marimbas, metallophones, vibraphones, glockenspiels and timpani.

Contact me (Bill) by phone: 0422 176 438.

e-mail: billv@westnet.com.au

I also offer some baic repairs to fretted and violin family instruments, and have of late been doing a number of repairs to the electrics of electric guitars. This might involve pickup replacement, or changing between active and passive setups.

I am able to carry out repairs on site. I am able to make replacement bars for most xylophones, vibraphones, marimbas and glockenspiels.

For anyone keen to do their own repairs, or wanting tips on how to look after their classroom instruments, go to my Instrument maintenance and repairpage.

This page describes repairs to various classroom instruments. I am intending to start including common repairs to concert instruments. If you have any questions, please ask.

I have also recently started putting some short videos on you tube to show some common repairs. You can search my name, Bill Vrijens, or Musaics.

My first video introduces Vibraphone Belt Replacement. Please open this in a new tab.

Replacing Rubber tubing on Xylophone and Metallophone Shows how to replace the rubber tubing under the bars of xylophones and metallophones. Please open this in a new tab.

Musaics Bass Xylophone Introduces the Musaics Bass Xylophone currently on sale. Please open this in a new tab.

The following lists some repairs carried out on various tuned percussion instruments.

Repairs to Xylophones, Marimbas, Vibraphones, Glockenspiels, Metallophones

This includes replacing rubber and felt parts, manufacturing frame parts, making and re-tuning bars (or keys).

Many instruments in this category are no longer made, or are just plain difficult to get parts for. I have access to someone with a very comprehensive engineering workshop who is able to make most unobtainable parts.

I have a range of alloys and timbers available to make new bars for most instruments.

Common Xylophone Repairs

This Korogi bass xylophone represents a common repair. This instrument was unplayable due to perished rubbers and broken pins, but was otherwise in sound condition. It is now, despite some character building evidence of extensive use, as good as new.

Converting Chromatic Extensions into Something Useful!

This was a chromatic extension, the part of the xylophone with the sharps and flats, or "black notes" that has been converted to a diatonic. Retune a few bars, and add a few new bars (which I make) and it's a useful instrument from something that is rarely if ever used. If the original 5 bars are there, it needs an additional 10 bars to include F#'s and Bb bars. The instrument however will only go G, so is one note short of the usual range, which goes up to A.

Many schools have these extensions stored away, rarely, if ever used. This way they can reclaim their place in the classroom and become more useful.

The cost of this conversion is $220. Which of course is around half the price of a new one.

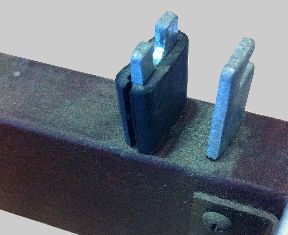

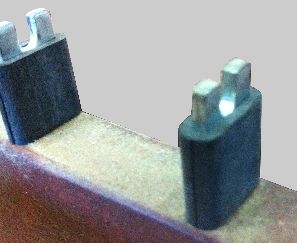

The Problem of bent Pins

When students just don't get it about taking bars of xylophone so as NOT to bend the pins, there is this option.

This involves attaching a piece of timber, as shown in the photographs. With this in place, the end of the bar pushes on the added piece and levers the bar off without bending the pin. They can't bend it even if they try!

I can't guarantee you'll never replace pins again, as the classroom is an unpredictable place, but I haven't replaced any pins on instruments with this modification yet.

When bending pins break things

This is a typical problem with instruments that have pins that are stronger than the wood they are nailed into. Pick up the bars incorrectly and they wreck the woodwork, as the plywood timber is easily damaged if the bars are not taken off carefully, as shown in the following photos.

looks pretty bad, but these are easy to fix, at a fraction of the cost of a new instrument, and my solution makes it better than the original.

The timber needs to be glued back together, and reinforced on the outside. In doing this I add a piece of timber as shown in the following photograph. This makes the instrument stronger on this edge, and prevents pin bending, even if you try. Picking up the bar on the end opposite this modification just supports the end of the bar so the bar cannot bend the pin as it's lifted.

The cost of this modification is $50.

The rubber that covers the pins and supports the bars is also easily available, and very easily replaced.

Glockenspiel Repairs

This is a common classroom glockenspiel, which has in the past been sold in large numbers in various brands and with small variations in appearance. They are metal bars on a wooden frame.

Repairs to these instruments are often more expensive than a new replacement, but it very much depends on the condition. The condition of the felts often requires all the bars to be removed. This is not to bad as long as the frame is sound, but if the frame is coming apart, which is common, or it is also missing bars, then repairs can become unpractical.

I do have a number of spare bars and metal pins with the mushroom shaped rubber sleeves for most variations of this type of glockenspiel, so anyone wanting to repair them can contact me. Repairs to these glocks are time consuming, but very straight forward. Removing the bars is simply a matter taking out the pins by gripping them with pliers and twisting anti clockwise, as if to unscrew them. Sometimes they use screws. I usually replace the felt with a strip I have cut from a length of felt often used on the feet of furniture. The frame can usually be repaired by anyone with some woodworking skills.

Vibraphone Repairs

This Saito vibraphone was purchased as a frame only, as the bars were missing. The complete set of bars have been

handmade here at Musaics, and anodized to resemble the colour of the original bars.

Unfortunately the Saito company no longer exists. I have found ways around replacing certain rubber parts, and many other parts I am able to make or have made.

More Vibraphone Repairs

This Trixon vibraphone was brought in missing the diatonic bars. A new set of bars was made to match the old chromatic ones.

My first entry into polishing metal bars to match existing ones.

Refurbishing an old Leedy Glock.

This old Leedy Glockenspiel was brought in, missing a few bars, and the case in a sad state. I have made a new case for this instrument, and used a piece of Perspex as the bass to give it that bright sound and a bit more projection. Works great! Bit hard to replicate the sound in the missing bars. Happy to hear from anyone with suggestions as to which steel to use which best replicates the sound of these old Leedy glocks.

Djembe Repairs

I have seen many of these sort of Djembe drums appearing in music classrooms, and have started repairing them. The main issue of course being broken heads.

The one shown here has had a skin or head, replaced. Replacing these can be costly, depending on if the drum was made with a standard head size. If this is the case then it requires undoing the rope, and doing it all up again. Takes a while. If the drum is an unusual size, a skin has to be lapped on to the original flesh hoop, which is another process, and takes longer, at more expense. The reason I go into this is to focus on the care required in taking care of, and storing these djembes. Because the heads often use an animal skin, they are very subject to the climate in the staff room. These drums often come in a padded carry bag, which should be used as much as possible in storing the drum. Good insulation against temperature and humidity changes. This does not happen in school situations, so some thought must go into storing them. It is highly recommended to store them away from windows, especially north or west facing windows (in Australia). Sore them in a cupboard, and if possible throw an old doona over them.

Another recommendation is to purchase Djembe's constructed in the manner of this one. It does not have a rope tensioning system. They often have synthetic heads, which is much more classroom friendly. The heads are very easily replaced. Undo the tensioning nuts and pop on a new head, and tension up again. I you have a standard replacement head this could take around 10 minutes, as opposed to 3 hours or so to lap a new skin on the hoop, and tension the whole thing on with rope. It is also much easier to tune or detune the heads as required. If you have to transport in a car on a hot day, just undo each tension bolt one or 2 turns and your safe. Tensioning up and de-tensioning a rope Djembe is possible, but you need to know what your doing, and it takes time.

Resonator Guitar Modifications

Resonator guitar Hotplate modification.

I had to try this out after seeing the National Resonator guitar Hotplate modification. Pretty straight forward. Take the cone cover off, fit a pickup and wire in volume, tone and output jack. The most difficult part is making the hole for the pickup. Here I used a friends milling machine, which allowed me very high accuracy.

This one uses a Duncan designed single coil, and sounds pretty reasonable. The National Hotplate uses a Lalor lipstick style pickup. I used this pickup as I had it on hand.

The advantage here is that no mods were required to the rest of the guitar. No cutting holes in the woodwork. To return the guitar to it's former self just replace the cover with a new one. Done in a few minutes. This also puts the pickup in a different position to mounting it in the body, which puts it closer to the neck. In this position its a bit more towards that middle pickup sound, with a little more bite than when fitted in the body closer to the neck.

The cost of this modification is $300.

Premier Vibraphone and Xylophone rubber post insulators.

This rubber peg is used on Premier Vibraphones, and a slightly different version on the Premier xylophone. The one pictured with black tape around it

resembles the state

of many of these pegs on vibraphones around the world. The new one shown simply slips on the metal fitting.

I have currently run out of stock of these. For anyone looking for these, I suggest you contact Paul Jefferies from Orchestral Percussion in the UK.

Unfortunately the quality of Premier's after sales service and parts supply stands in direct contrast to the quality of their instruments. This would have to be the worst company ever for parts availability. Surely if enough people world wide continue to demand some service someone there will one day take notice? I was told by them, when asking about parts for a xylophone many years ago, that surely I could not expect parts for these instruments, as they had stopped making that model (very recently). That to me compares to a company like BMW or Mercedes not making parts available once they stop making a certain model. Imagine how that would go down?

Premier Vibraphone damper bar ball joint connector.

This socket is used on Premier Vibraphones to attach the upright arm from the damper pedal to the damper bar.

It is a plastic ball joint. The most common problem is that the plastic ball cracks, and rod won't stay in place. English engineering!

I have now run out of these parts, and the search is on for a small ball joint that can be retrofitted. A metal ball joint should last forever in this situation.

Japanese Vibraphone and Xylophone rubber post insulators.

The photo on the left shows an old and perished peg rubber (often called Bar Suspension post Insulators) on a Saito Xylophone. The photo on the right shows a new rubber replacement. I suspect that all the the rubbers on these Japanese made vibraphones and xylophones are the same. Need to confirm this though. Saito parts had not been available for a couple of years at time of writing this (August 2019), but I was told this could change.

As an alternative, I have started using heat shrink, and have outlined this process in the repairs article Instrument maintenance and repairpage. It does require the use of a heat gun, but is very straight forward. If you want to replace all the rubbers on your instrument, the heat shrink is inexpensive. A cheap heat gun is probably worth the investment, as the total cost will still be less than buying the parts, if you can get them.

Speed controlled DC motor for vibraphones

Trying to solve the problem of an affordable small DC speed controlled quiet motor for a vibraphone has been an ongoing project. The photo here shows a motor and pulley setup that was designed to fit onto an old Premier blue frame vibraphone. It uses a very small brushless geared DC motor. The speed control uses a readily available 12 volt Pulse Width Modulation (PWM) device. This worked perfectly, except it is still too noisy. The quest for a brushless low voltage DC motor that is quiet continues. Because of the slow speed required, these motors need to be geared. The gearing causes noise. Brushless DC 3 phase motors may be the answer, but controlling them is tricky, and they still need to be geared.

The aim, which this little motor was able to do, is to have a setup that can be powered by a standard plug pack (wall wart), or batteries, which means the vibraphone is free of any 240 volt safety issues or concerns. Unfortunately it is still to noisy.

This is the first such motor setup I have used with a brushless DC motor, but I have used a similar design with a brushed motor a while ago, which had more noise issues.

Any advise or technical suggestions appreciated.

Repairs to Timpani

Timpani repairs include general servicing, clearing and replacing heads, replacing teflon tape on rims, and general repairs. I am happy to service and repair timpani on site, when possible.

This repair involved replacing parts that had disappeared from the clutch assembly ofn a Premier timpani pedal. A simple fix if the parts could be available, but, Premier doesn't believe in supplying parts. They'd rather you buy a new timp!

Having access to a very clever friend with a comprehensive machine shop, I was able to have a replacement made. It was easily fitted.

This Pearl timpano had a worn pedal mechanism. Not much to adjust on these timps, but when they wear they get to a point where you need to replace several parts. Replacing these parts makes these work as good as new. This particular repair cost $220, which included pickup and delivery (it was very close by).

Instruments that use velum heads

Many older instruments of the banjo family do not have standard size heads. Here the only option is to refit a piece of velum to the old hoop. Takes time, but on good quality instruments it's often worth it.

A word of warning. There are a number of these sort of instruments around that are being bought by people who want to have

them restored so they can be played again. Many older instrumensts were not well constructed, and Instruments that are stored away in slightly damp attics or garages often

resurface with a number of issues. To replace the velum on a non standard instrument will cost a bit,

and banjo mandolins have 8 strings, so that's a bit of tension on an old neck. I have strung up old banjo mandolins after

some refurbishment only to see the neck slowly bend to the point where its unplayable. If you are wanting an

instrument to play, you may be well advised to just buy a new cheapy rather than that nice old looking instrument

with all that old time charm on eBay.

And of course there are always those odd projects.

This is an instrument not often seen. First time I'd seen them when recently someone sent me an entire set for repairs. They were missing mallet heads, rubbers, many broken handles etc. One was missing completely.

These instruments are easily dismantled, and if the parts were available, replacing broken parts would be easy. Unfortunately, the English company that makes them completely ignored my emails. Obviously not interested in assisting in this way.

The photo shows the one I made as a replacement.

This project involved converting a standard guitar amplifier quad speaker cabinet into a combination 2 x 12 sealed and 2 x 12 open back speaker cabinet. I know, it's not a tuned percussion instrument, but, well, it was for a friend of mine.